RTU Curb Guide: A Guide for Mechanical Contractors Working With MFAB

- Charles McCarthy

- Jan 4, 2024

- 4 min read

The purpose of this guide is to establish working standards for MFAB and the contractors MFAB is providing RTU curb welding services to. We perform over a hundred RTU installations every year and have found that if the guidelines laid out in this manual are followed by both MFAB and the Mechanical Contractor/GC curb installations move smoothly and profitably for all companies involved and there are never any reworks required.

Info Gallery

Site Conditions and Estimation for RTU Curbs

MFAB provides fixed pricing for the fabrication and installation of Roof Top Unit (RTU) curbs, exhaust curbs, and make-up air curbs (MUA) when working in an empty shell. Our pricing is determined on a per-unit basis, taking into account the size and location of the curbs on the prints, as well as the timelines/working hours specified by the customer.

The pricing is based on certain assumptions, and if the actual on-site conditions differ from these assumptions, MFAB may charge you time and materials at our current T&M rate or submit a change order for any additional time required to complete the quoted work. If such a situation arises, MFAB will promptly notify the General Contractor (GC) or HVAC contractor before commencing any additional work. We don't want to do this but wasted time is wasted money. This is why we created this guide.

To minimize the likelihood of change orders or T&M billing, MFAB strongly recommends scheduling our services immediately after the slab is poured or demo has been completed and before other trades access the space. This approach allows MFAB to install RTU curbs within the joists before any ground or air obstacles are introduced to the job site.

Assumptions Made

The jobsite is clear of obstacles, with no electrical, plumbing, drop ceilings, steel stud framing, or HVAC equipment/ducting hindering access to work locations on the ground or in the air. If construction materials such as drywall, wood, or ducting obstruct access, MFAB will relocate these obstacles at T&M rates.

The locations where RTU curbs are to be installed is accessible with a scissor lift. MFAB does not install RTU curbs off ladders for the safety of our employees.

Unless explicitly specified and requested by the GC or Mechanical Contractor, MFAB includes a scissor lift in our pricing and manages all associated logistics to avoid this potential problem. However, if you wish to provide a lift you must ensure that it is on-site when MFAB arrives to perform the work and must be available for MFAB's use throughout the entire duration of our presence on-site. Sharing the scissor lift with other trades slows us down and adds more costs to the project.

The locations and inner dimensions of all curbs should be marked on the underside of the roof decking with highly visible spray paint or a permanent marker. This layout style precisely indicates curb locations and internal dimensions. Using painters tape for layout and spray painting along the tape produces the most accurate markings in our experience (See Detail 5).

If a curb's location or dimension is extremely critical, it must be explicitly called out and communicated to MFAB's curb installers with a properly dimensioned and precisely located square/rectangle on the ceiling. For example, when a curb spans one or more bar joists, and an intake or return is on either side of the bar joist.

Bar joists/decking are free from insulation/fireproofing material.

MFAB does not work in an environment requiring extensive protection from sparks that necessitates extra time and labor to prevent fire damage (e.g., epoxy floors, extensive plastic sheeting).

Parking must be available within 150ft of the work location or access to 220v power with a NEMA 14-50R receptacle must be provided.

Any other trade working concurrently with MFAB in the space is adequately protected from welding rays, or they will be responsible for providing their protection.

The jobsite floor is free of extensive obstacles requiring maneuvering, such as plumbing trenches.

Job Conditions

RTU curbs are quoted spanning a single Bar Joist. If the curbs need to span more than one bar joist, MFAB must be informed before providing a quote.

Unless otherwise specified in the contract drawings by the Engineer, MFAB quotes RTU curbs using 4x4x1/4" angle iron. (Based on MFAB's experience, this is the standard for 90% of RTU Curbs.) If anything varies, we will not it in the description on the contract.

Vertical joist bracing is not included if not shown on prints. If vertical bar joist bracing is necessary and not shown on the prints, additional costs will be incurred.

RTU are not painted or primed by MFAB.

All work is to be conducted during regular business hours. Night and weekend work is billed at overtime rates.

No coping of the angle iron is necessary. MFAB measures the distance between bar joists with a laser tape and cuts the angle to allow for butt welds.

We do not install angle iron on top of joists. This detail is typical in new construction, where ironworkers can drop prefabricated curbs in place before installing decking. On remodel work it requires breaking the decking free from the joists which either means breaking the puddle welds that hold the decking down or breaking the deck screws.

If a curb lands on a firewall, MFAB will remove enough drywall to perform the curb installation but will not be responsible for patching the drywall. (See detail 6.)

If demolition work is required on the part of MFAB. If old curbs or ducting must be removed, this must be communicated before bidding on the job, any additional costs as a result of demolition will be on a T&M basis.

Detail 1

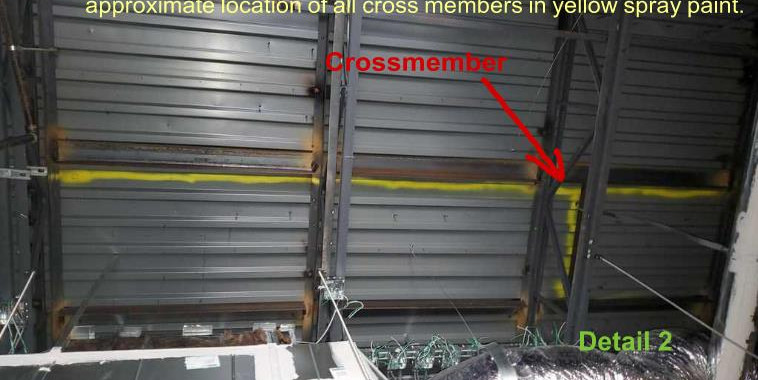

Detail 2

Detail 3

Detail 4

Detail 5

Detail 7

Detail 8

Detail 9